EPPsys D

Specification

-

Overview

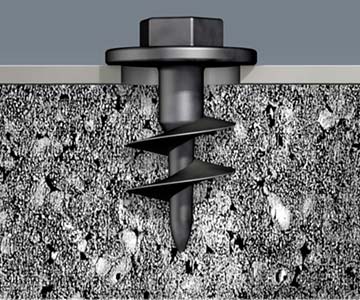

- Use of the special EJOT thread for EPP foam

- Ideally suited for tolerance independent assembly, because no pilot hole is necessary

- High process reliability due to large margin between installation and stripping torque

- Easy assembly after the foam expansion

- High transmittable tensile forces

- High torques

- Weight savings due to used plastic material

- Recyclable

Hotline

Applications Engineer

Direct fastening of EPP foams!

As all fastening elements of the EJOT® EPPsys product group the EPPsys DR screw has also been developed to fasten components to foamed parts, especially EPP foams (expanded polypropylene). Easy, quick and secure: The EJOT® EPPsys D screw ("Direct assembly") can be directly and easily fastened into the foam. Using specified torques and adjustable torque limiting drivers, the EPPsys D screw can be installed into EPP foams (with large density) in a process reliable way.