EPPsys RSD

Specification

-

Overview

- Friction welding geometry specifically developed for EPP foams

- Ideally suited for tolerance-independent assembly because no pilot hole is necessary

- Easy assembly after the foaming process

- Special drive bits available for the different drive geometries

- Usage in foam densities from RG30 to RG250

- Weight savings and recyclability thanks to the use of polymer material

- Available in large (22mm) and small (12mm) diameters as an insert for use with EVO PT® screws Ø 5mm and 6mm

Hotline

Applications Engineer

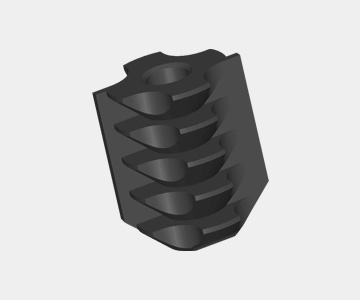

Friction welding insert for EPP foams

The EJOT® EPPsys RSD („Reibschweißdom“ = friction welding boss) is an effective fastening element for EPP foams. The innovative friction welding process directly embeds the fastener in the EPP foam and securely connects it to the molten material. Then the EPPsys RSD enables easy and reliable direct fastening with the EJOT EVO PT® screw.

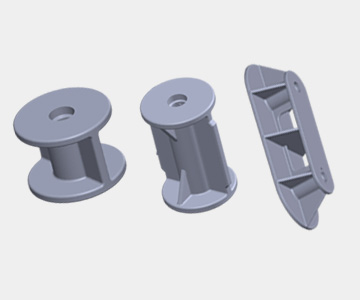

EJOT Delta Tubus as an alternative to friction welding

If the EJOT® EPPsys RSD and its assembly after foaming are not suitable for you, it is also possible to create a joint with our Delta Tubus elements. These parts are inserted into the mould before the foaming process and subsequently surrounded by the EPP or similar foams. Thus, after opening the mould, you get a finished component that already contains the joining elements. EVO PT® screws 40 or 50 are used for fastening in this case.

Easy insert solution with the EPP insert

The EPP insert is the easiest solution for creating a screw-in option in foams. This element can be pressed into pre-drilled components thanks to its special ribbed geometry. No special assembly technology is required here – all that is needed is to ensure that the foam component has a pre-hole. This can be drilled or already created during the foaming process. The EPP insert is available with a metric M5 thread. Further hole geometries upon request.

![[VBT_EVO_PT].png](/medias/sys_master/products/products/h0d/h92/9356537593886/135Wx135H-.png)